Carbide End Mill

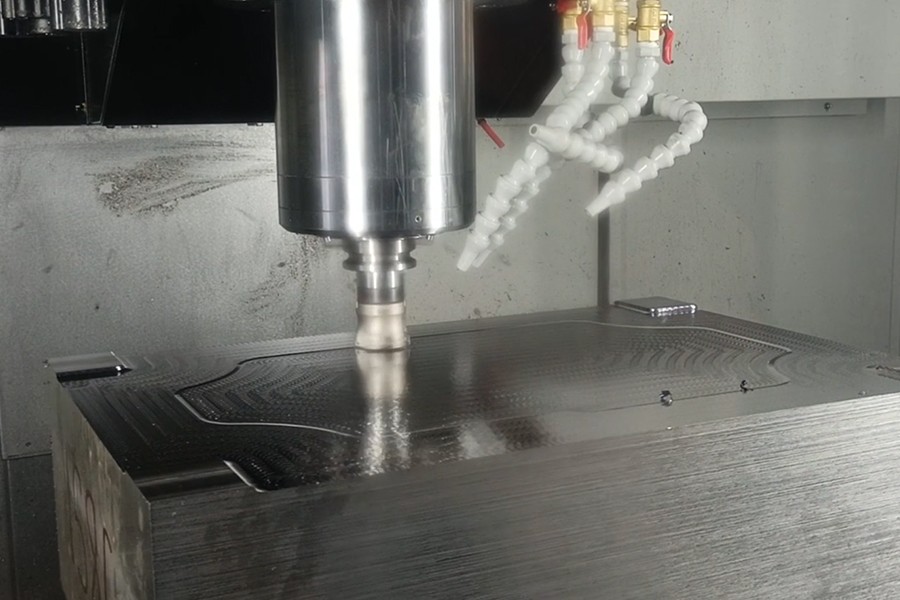

Diamond milling cutters are machining products that are turned into a final product suitable for the workpiece by forming and coating on grinding machines using cylindrically sintered and ground raw materials.

How to Choose Carbide (Diamond) End Mill?

Let's realize that there is a workpiece that you need to machine or shape; Choosing the right tool is very important for drilling, roughing, intermediate roughing or finishing operations on this workpiece. First of all, considering that your machine, you and your employees cost a certain amount of time, it is most important to have a team that will solve your job quickly and take you to the solution quickly. In addition, it is an indication that a fast-wearing diamond cutter will increase your costs and decrease your profit margin and you will not be able to receive offers.

First of all, it is necessary to take a look at whether it is a machine part or a mold component that you are going to process. In general, it is necessary to use more standard tools, as not much precision is required in the stationary parts of a routine machine part and too much chip removal is required.

However, High Feed tools are recommended if you have a strong machine and a large volume of chips that need to be removed. If you are machining cast or fabrication steels but want to keep your machining costs low, you should choose standard tools. These tools are manufactured from more suitable carbide rods. And again, suitable coatings are used, as an example, a TiN or TiAlN coated carbide mill with 30° helix angle and 0.6micron grain size.

However, if you are machining a mold part, it is recommended to use more precise tools at this point.